20 September 2023| By: Abdullah Hussein

Gas hydrate is one of the biggest flow assurance threats in oil and gas fields.

While managing gas hydrates can be done in a variety of ways, the best approach must be carefully chosen based on the project economics and a thorough risk assessment study. In extreme situations, a mix of techniques may be required.

In general terms, gas hydrate mitigation can be achieved in three main ways: operational, chemical, and nonchemical ways. The first two methods are very common in field practice, whereas the latter is not very common. These methods will be discussed briefly in this article.

Fig.1: methods of mitigating gas hydrate

- Operational methods:

These methods encompass adjusting system parameters to operate in hydrate-free or hydrate-safe zone. These methods include:

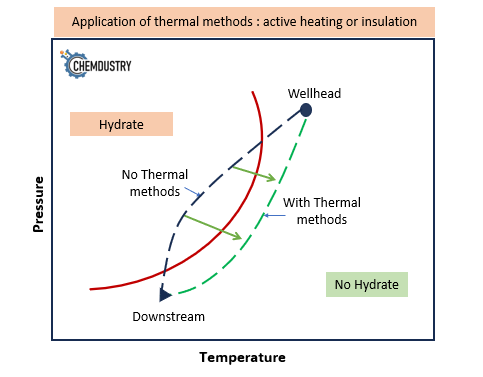

- Maintaining system pressure and temperature outside the hydrate formation zone. Temperature and heat management can be achieved using active heat, or passive insulation methods, which keep produced fluids above the hydrate formation temperature (Fig.2).

Fig.2: Effect of thermal methods in treating gas hydrates

- Gas dehydration methods eliminate the water that is necessary for hydrate formation. This is achieved using conventional dehydration processes, besides using routine pipeline pigging and drying to remove any water or moisture in the pipelines.

- Cold flow is a gas dehydration method and also a gas hydrate prevention method, since it allows controlled precipitation of hydrate crystals in a slurry form that can be transported safely to the desired destination.

● Chemical methods:

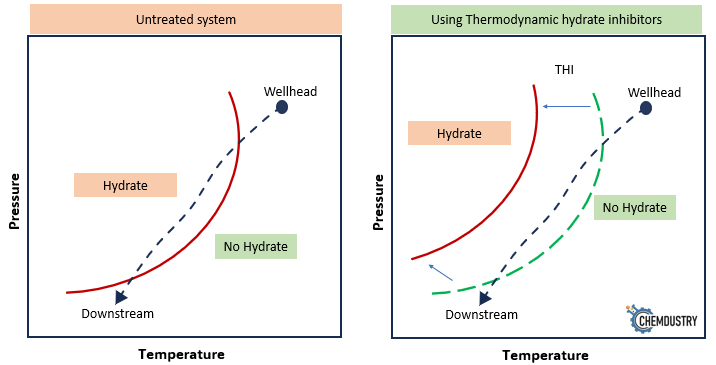

- Thermodynamic hydrate inhibitors (THI): such as MeOH and MEG. These chemicals change the thermodynamics equilibrium by shifting hydrate formation temperature to lower values and pressure to higher values, which extends the hydrate free zone for production (Fig.3) . THI are applied at very high dose (up to 60% of the overall water)

Fig.3: Effect of THI on hydrate equilibrium

- Low dosage hydrate inhibitor (LDHI): these chemicals slow down hydrate formation process. This category includes kinetic hydrate inhibitors (KHI) and antiagglomerants (AA). LDHI chemicals are applied at low dose (0.2-3% of the overall water)

THI and LDHI chemicals are very crucial during shutdown operations to avoid system full blockage.

● Nonchemical methods use physical means to avoid gas hydrates formation such as internal coating, ultrasonic methods, and biological methods.

Gas hydrates removal also involves operational, chemical, and nonchemical methods. WARNING: Gas hydrate plug removal can be very dangerous (fatal) and must be designed by GH specialist in collaboration with HSE and process engineers.

Depressurization method:

In this method GH is dissolved by lowering system pressure to be below formation pressure. The method is considered effective, but can be time-consuming, and entails safety issues such as projectile hydrate plug which can be fatal, specially if depressurization is implemented from one side.

Thermal methods:

By applying heat above the hydrate formation temperature to dissolve the GH plug. These methods are very effective but can have some safety issues, as in depressurization method.

Chemical methods:

THI are considered GH dissolvers and commonly used to dissolve hydrate plugs. Furthermore, THI is also combined with other methods (depressurization, thermal, and mechanical) to prevent GH re-precipitation after removal, and to avoid hydrate projectile plug. LDHI chemicals have also been used with THI to remove GH plugs.

Mechanical methods

Common examples are pigging and coiled tubing. Pigging is used to remove soft GH deposits, and when the pipeline is not fully plugged. coiled tubing has been successfully used to remove GH pugs in pipelines and in wells. Chemical agents such as THI are usually used with these mechanical methods to improve its efficiency.

Good GH plug removal combines different methods, such as mechanical+ heat + chemical methods by applying coiled tubing in addition to heated THI which accelerates the GH dissolution kinetics.

Gas hydrate mitigation