24 February 2024| By : Abdullah Hussein

One of the most challenging issues in oil and gas operations is gas hydrates. They are ice-like solids that usually form at low temperature and high pressure when water molecules form cages that entrap natural gas molecules.

Gas hydrates pose a significant flow assurance risk in different oil and gas fields around the globe. They are considered a major challenge for deepwater drilling operations as well.

Fig.1: Gas hydrate plug (photo credit Bill Schmoker (PolarTREC 2010), © ARCUS Polar Media Archive)

The problem is not limited to the operational challenges, or the cost of mitigation, but more seriously related to the safety concerns associated with hydrate plugs mitigation and removal, which require a well trained and experienced team, a well designed removal plan, and usually sophisticated techniques.

Generally speaking, the challenges associated with gas hydrate plug removal include:

- Unsuccessful hydrate plug removal. And this can be more disappointing after spending a long time on plug removal trials.

- Release of toxic and flammable gases. When the plug starts to slowly dissolve, H2S and other hydrocarbon gases are released, which make a toxic and flammable mixture. This also entails a fire hazard.

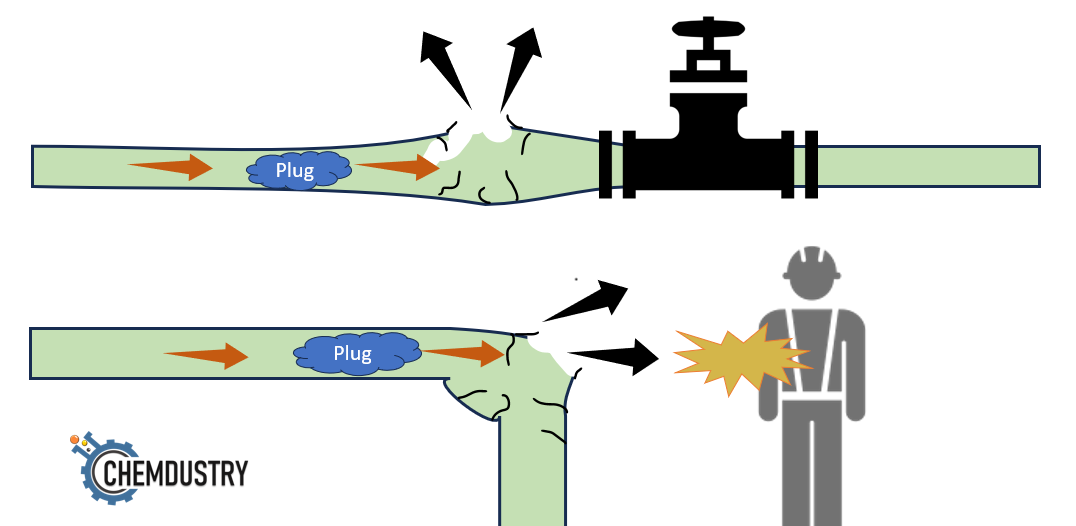

- Projectile hydrate plug. This usually happens during plug removal when the plug is depressurized improperly (commonly during single-sided depressurization) causing large pressure gradient across the plug. Once the plug is partially dissolved and dislodged from the pipeline and by the effect of the pressure gradient, the plug or the debris around it will be launched as a projectile, causing pipeline rupture, equipment damage, and potential fatalities. This is depicted in Fig.2.

Fig.2: Problems associated with projectile gas hydrate plug during improper depressurization: pipeline rupture, equipment damage, personnel injuries or fatalities.

Fig.2: Problems associated with projectile gas hydrate plug during improper depressurization: pipeline rupture, equipment damage, personnel injuries or fatalities.

Plug removal is a complex process. It usually takes a highly experienced team to design the removal program to avoid any equipment damage personnel injuries, or any other environmental issues.

Generally speaking, a safe and efficient GH plug removal requires the following:

A skilled team: usually includes but not limited to :GH specialist, process engineer, production chemist, and HSE officer.

Consider worst-case scenarios: multiple plugs, projectile plug, pipeline rupture, etc.

A robust safety risk assessment for all these potential scenarios and a feasible emergency plan.

Above all, patience , since the plug might take weeks to budge.

Let's take a closer look at the considerations that the gas hydrate plug removal team has when designing the removal program. The removal of the plug essentially hinges on:

- System design

- Plug location: well, flowline, etc.

- Plug properties: size, strength.

- Available removal methods

Now, what methods are usually employed to remove GH plug? There are plenty of them, You can use one or combine multiple methods to get the best efficiency. Let's take a brief look at these methods

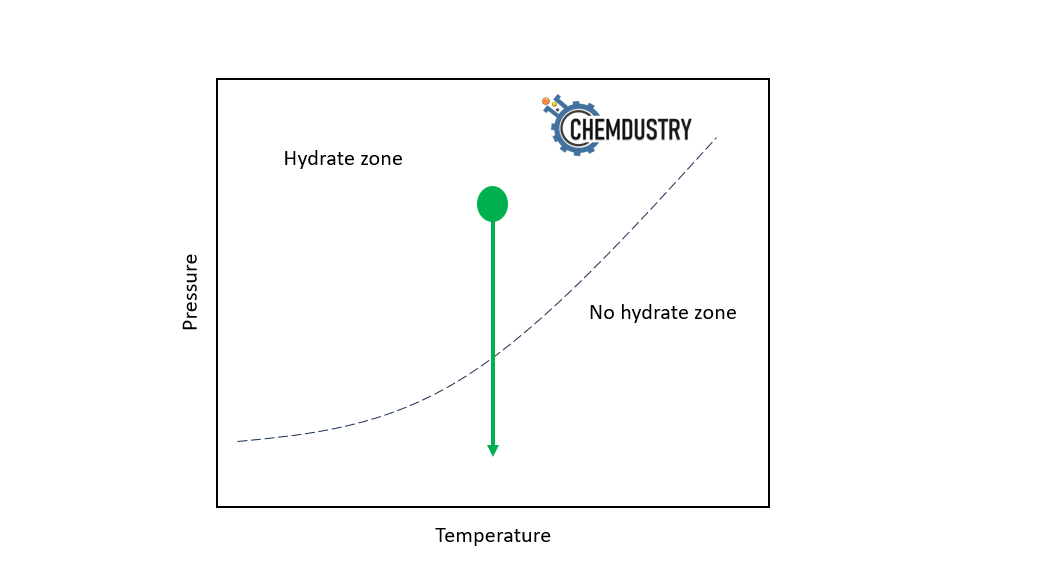

1- Depressurization

In this method, pressure is reduced until hydrate dissociation conditions are reached. Depressurization is recommended to be done from both sides of the plug, which is known as two-sided depressurization. Two-sided depressurization might be restricted due to accessibility from both sides of the plug. One-sided depressurization has been used, but in some incidents, it might cause a high-speed projectile once the plug is partially dissolved, as mentioned above. One-sided depressurization is recommended to be used when two-sided depressurization is not available, and after doing a proper risk assessment to avoid any unexpected events.

Fig.3: Plug removal using depressurization

Depressurization method pros and cons :

Pros:

- Efficient

- Economic, but can be costly with extended time of plug removal.

Cons:

- Slow process, as plug removal might take days or weeks.

- Depends on system design and complexity.

- Can result in ice formation or a harder plug if it is done improperly.

- Entails safety issues including pipeline rupture, equipment damage, toxic and flammable gases, personnel injuries, or fatalities.

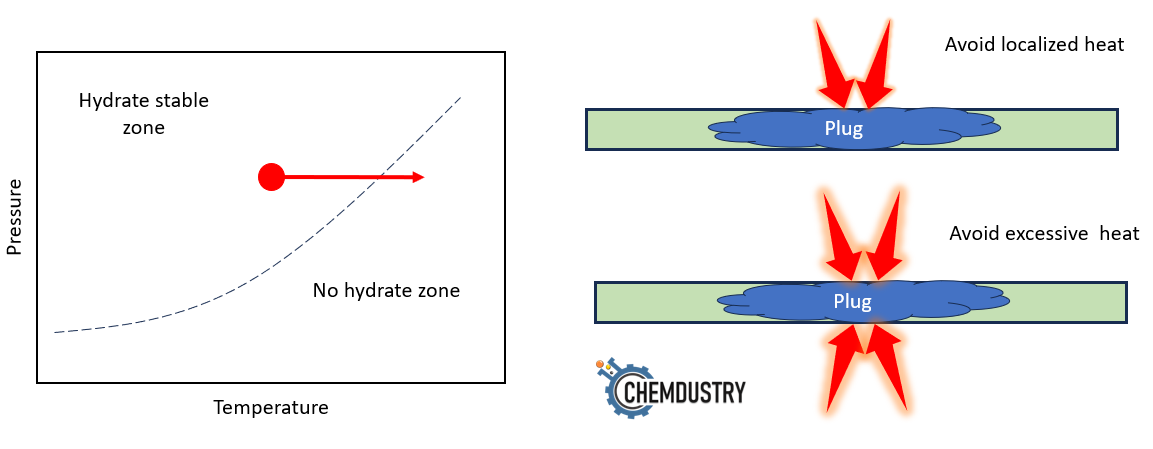

2- Thermal methods

In the thermal method, external heat is applied to raise the pipeline temperature above the formation temperature, which aids in melting the GH plug. Electrical heating methods, or hot fluids circulation, are usually used. Heat must be applied evenly on the plug’s ends to avoid pressure buildup from dissociation, to avoid pipeline rupture, Fig.3.

Fig.3: Precautions of heat application during GH plug removal.

Thermal methods pros and cons :

Pros:

- Efficient method

- Relatively fast.

Cons:

- Safety issues, due to pressure buildup and possibility of pipeline rupture and personnel injuries.

- Could be costly process.

3- Chemical methods

Thermodynamic hydrate inhibitors (THI), such as methanol and glycol, are usually used to dissociate GH plugs. They work by shifting the GH thermodynamic equilibrium.

The dissociation efficiency depends on the chemical's properties, such as density, viscosity, and vapor pressure. Generally speaking, THI's usage is as follows:

- Low density THI, such as methanol, is more efficient for softer GH plugs or accumulations and is commonly used for GH plug removal in pipelines.

- Higher density THI are efficient with harder plugs and commonly used in plug removal in wellbores.

THI chemicals are usually applied during depressurization and thermal removal to work as cushions to prevent projectile plug, and also to prevent re-precipitation of GH after dissociation.

Low dosage hydrate inhibitors (LDHI) were found to enhance the efficiency of THI during plug removal, and to prevent re-precipitation of GH after dissociation.

Another category of chemicals is the heat generating chemicals which include multiple chemicals that are sent to mix near the area of interest, to start a reaction that generates a significant amount of heat to melt the plug.

Chemical methods pros and cons :

Pros:

- Efficient.

- Can be used with other methods to improve the dissociation.

Cons:

- Can be slow, depending on the chemicals efficiency and the plug properties.

- Require good delivery to plug location to make good contact for dissociation.

- Chemicals can be costly, specially in cases of multiple plugs and in long pipelines.

3- Mechanical methods

Numerous mechanical methods, such as pigging, scratchers, and coiled tubing, can be employed. The application of these methods depends on the plug location (wellbore, piggable or non-piggable pipeline, subsea, topsides, etc.), plug properties (soft or hard) , system design, and accessibility.

- Pigging is used to remove soft plugs, and when the pipeline is not fully blocked. It is possible to enhance the GH removal by adding THI chemicals, the chemical will also prevent GH re-precipitation.

- Coiled tubing (fig.4) can be used in both pipelines and in well cleaning. It encompasses the mechanical action, chemical circulation, in addition to the ability to use the heat by circulating warm chemicals.

Fig4: Coiled tubing unit (source Wikipedia)

Tips for good GH plug removal:

- Combination of methods is recommended.

- Always maintain pressure control to avoid pressure buildup (causing pipe rupture, or making the plug harder to remove). Besides, sudden uncontrolled pressure drop can cause J-T cooling, which in some instances might make the plug harder to remove. Ice formation is also possible due to uncontrolled pressure and temperature.

- Applying heat must be even on the plug to avoid pressure buildup, which might cause pipeline rupture, and personnel injuries.

- Chemical should be used all the time to work as cushions to avoid projectile plug, and to prevent the re-precipitation of hydrate.

- Coiled tubing is considered an all-in-one method: mechanical force, heat, and dissolving chemicals.

-------------------------------------------------------------------------------------------------------

Further Reading:

- Chapter 16 - Gas Hydrate Management , Essentials of flow assurance solids in oil and gas hydrates

Gas hydrate plug removal (1)