6 December 2023| By : Abdullah Hussein

Microorganisms are known to cause various types of damages to oil and gas production systems, such as:

- Microbiologically influenced corrosion (MIC)

- Biofouling

- Reservoir souring

- Interfering with phase separation

- Chemicals degradation

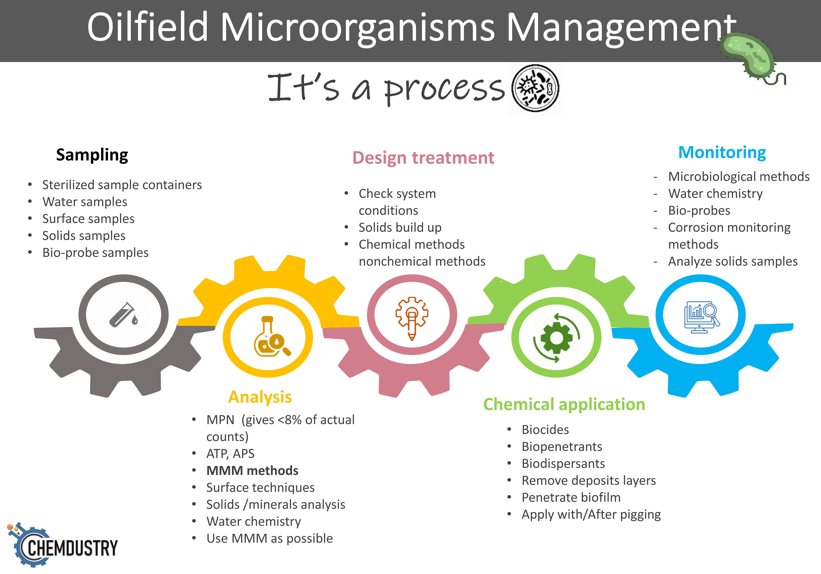

Additionally, it is recognized that microorganisms function through a variety of pathways and that they can both resist and adapt to certain treatments, which makes their management very challenging. For this reason, strict protocols should be followed when managing these bacteria. A few of these steps are illustrated in Fig. 1 and further explained in the sections that follow.

Fig.1: microorganisms management plan

Like other production chemistry issues, managing microorganisms entails risk assessments, appropriate treatment application, and ongoing monitoring to measure treatment efficacy. However, with microorganisms, a deeper investigation is necessary due to the multifaceted challenges associated with them. For example, in the case of the MIC problem, a thorough corrosion risk assessment is required in addition to investigating the existence of microorganisms and their contribution to the corrosion problem.

Sampling :

Samples can be produced fluids, solid deposits, and steel surfaces/pipes cut-offs. A few tips for proper sampling are below:

- Use proper sample containers; make sure they are sterile.

- sample size should be sufficient for microbiological tests and other chemical or physical examinations.

- Solids and surface samples are preferred since they contain the sessile bacteria that are more damaging and resistant to treatments vs. planktonic bacteria, which are normally tested in water samples.

- Sample preservation and storage are critical.

- Sampling after pigging: multiple samples from the pig body, in addition to a composite sample, are recommended.

- Bio-probe (Fig. 2), corrosion coupon, or scale coupon samples are good representations of the production system and can be used to capture the damaging sessile bacteria.

Fig.2: Dismantled bioprobe with the studs and Cosasco bioprobe in the red frame.

Fig.2: Dismantled bioprobe with the studs and Cosasco bioprobe in the red frame.

Analysis :

As mentioned above, microorganisms are a multifaceted issue. Thus, multiple tests and analysis are required. Here are a few tips for analysis:

- Water chemistry analysis is necessary to assess the risks of corrosion, scaling, and microorganisms.

- Culture based techniques (such as serial dilution or most probable number MPN) are common in use for microbiological analysis. However, these techniques only account for < 5% of the actual bacteria counts in the sample, and they are time consuming. Culture methods are detailed in standards API RP 38 and NACE TM-0194.

- Techniques such as Rapid Check and ATP give fast results about the existing microorganisms, which can be crucial, especially when treatment is ongoing.

- Microbiological methods (MMM) such as PCR, DGGE, and others are preferred. These methods are superior to the culture and rapid techniques in accuracy and recommended in complex cases. Some of these techniques are mentioned in NACE standard TM0212.

- Solids analysis, including both mineralogy and microbiological analysis, is necessary. Certain minerals are metabolic byproducts of bacterial activity, and this can be used as a marker for such bacterial activity. Microbiological tests of solid sample are conducted to determine the presence of sessile bacteria.

- Surface methods such as microscopy are used to determine surface properties, the extent of damage, and biofilm properties.

Treatment :

The operator should gather field data, history, and similar case studies in addition to the data gathered from the above testing and analysis. These should all be combined to create a risk assessment matrix that illustrates the extent of the issue. Based on this, a mitigation plan is designed and applied. In general, there are numerous ways to treat microorganisms, including chemical, nonchemical, and operational approaches. Here are a few tips to keep in mind before mitigation:

- Study the system design, conditions, and accessibility of the treatment method.

- Check solids buildup: solid layers must be removed to assure that treatment makes contact with the microorganisms.

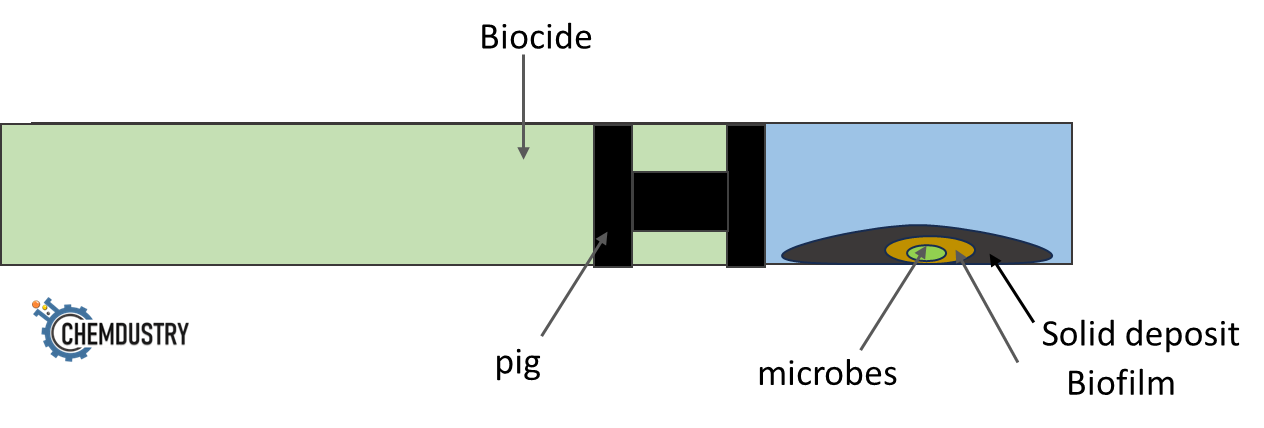

- For chemical methods, routine treatments include the injection of biocide chemicals into water systems for specific contact times at specific time intervals. Switching between two different biocide chemicals is necessary to avoid bacterial adaptation to the chemical. Select and use a chemical biocide that can penetrate the biofilm and kill the bacteria. If biofilm is hard to penetrate, try using biopenetrants or biodispersants with biocide treatment. Biocides are also preferred to be applied during or after pigging (considering this will not cause any further damage to the pipeline), specifically if there is solids buildup on the pipe wall, to make sure that the solids layer is removed, and biofilm and bacterial cells are exposed to the chemical slug (Fig. 3).

Fig.3: Applying biocide during pigging

Monitoring :

Continuous monitoring is required to assess the effectiveness of the treatment strategy and identify any microbiological problems as soon as they arise, ideally before they become serious. There are several ways to accomplish this:

- Frequent microbiological testing.

- Solids analysis, from pig returns and well gauging.

- Water chemistry.

- Corrosion monitoring methods.

- Bioprobes

- Sensors

- ILI and smart pigs

Oilfield Microorganisms Management