28 December 2023| By Abdullah Hussein

Wax gelation and deposition is a major flow assurance problem in oil and gas fields. Wax precipitation starts when the temperature of the crude oil temperature falls below the wax appearance temperature (WAT). This results in several challenges, such as changes in the crude's rheology and flowability, equipment damage, and pipelines blockages, which ultimately result in expensive maintenance, production downtime, and loss of revenue.

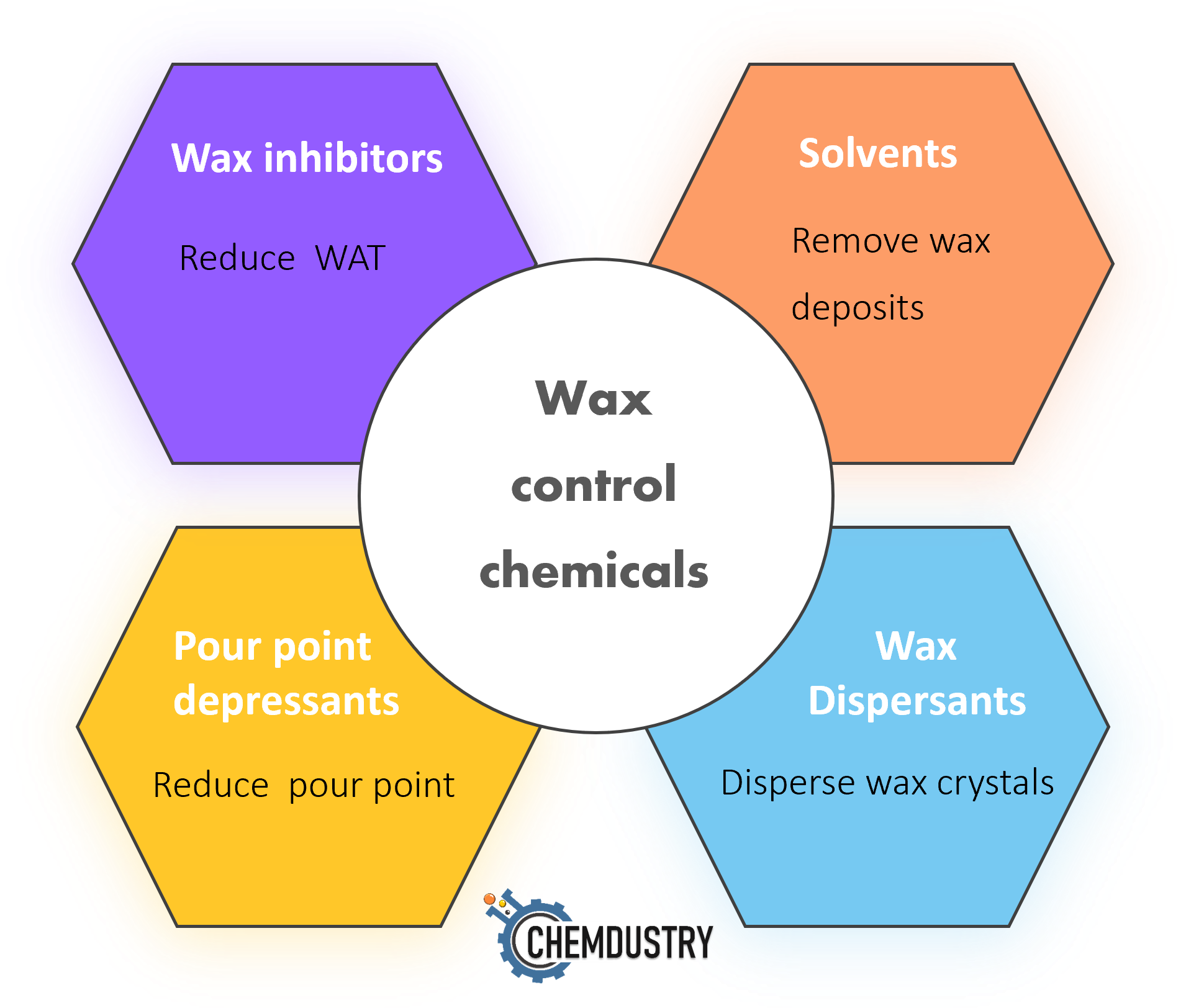

Wax issues are commonly mitigated using different types of chemicals, such as wax inhibitors (WI or PI), pour point dispersants (PPD), and wax dispersants (WD or PD) (Fig. 1).

Fig.1: Wax control chemicals

Fig.1: Wax control chemicals

The efficiency of these chemicals is usually evaluated in the lab prior to field application, through various tests such as:

- WAT measurement

- Pour point (PP) measurement

- Viscosity measurement

- Cold finger (CF) testing

- Flow loop testing

Although these test methods are well established and have been used for decades, in some cases, the tested chemical does not show the expected performance in the field, despite being deemed efficient during lab testing. This might be attributed to some factors related to the testing conditions, treating chemical composition, fluids composition, or a combination of these. Some of these factors will be discussed here briefly.

■ Treating chemical composition:

Wax control chemicals usually comprise bulky groups and side chains. The side chains co-crystallize with wax molecules, while the bulky polar groups impose steric hinderance, which interferes with and disrupts the wax network. The factors that impact the chemical performance here include:

Side chains lengths: it is recommended to match the length of the wax molecules with the side chain length of the treatment chemical, to facilitate the incorporation into the developing wax network. Knowing the carbon distribution of actual field deposits is crucial, since matching the treating chemical's side chains with the chains of the actual wax deposits should (theoretically) give the best performance.

Bulky /polar groups numbers and spacing between them: these affect co-crystallization and solubility in the crude oil and in the used solvent. Too many bulky groups might affect the chemical performance, besides affecting its solubility in the carrier solvent and the flowing stream.

Molecular weight: very high molecular weight affects the chemical solubility in crude oil and in the carrier solvent. A chemical might be effective in lab tests but shows incompetency in field application due to solubility/miscibility issues. Furthermore, very high molecular weight chemicals might have problems during their injection, such as junking in the small diameter injection lines, and at the injection points.

■ Fluids composition:

Wax chemicals have shown good performance with waxy crudes that are rich in cyclo and branched alkanes (due to the poor packing of wax networks), compared to crudes rich in very high molecular weight wax molecules >C40, as carbon number matching might not be possible.

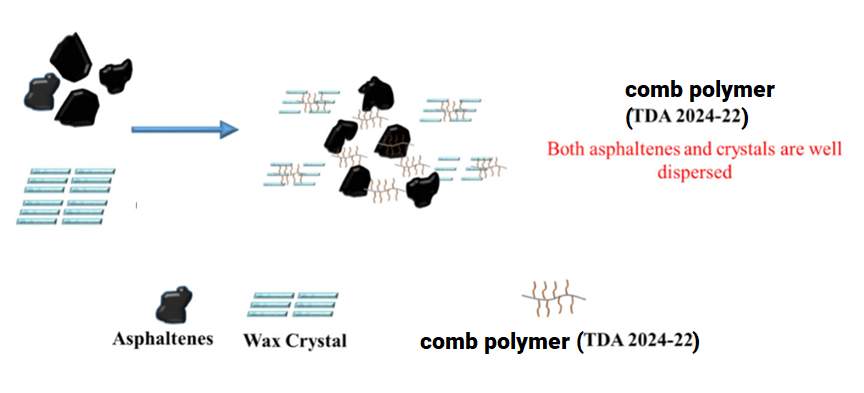

Asphaltenes can affect wax control chemicals in many different ways. Asphaltenes affect wax deposition; they can either decrease or increase wax deposition rates, and this, for sure, will affect the chemical performance if it cannot cope with the increasing wax deposition rates. Similarly, asphaltenes can directly affect the performance of the wax chemicals since they can consume some of the injected chemical by interacting with it, which in turn will reduce the effective dose of the chemical. For instance, comb polymers (common PPD) can interact with asphaltenes and stabilize them (Fig.2), which might come at the expense of wax molecules, specially when asphaltenes behave differently in the field compared to the lab during testing. Some reports showed that, asphaltenes can also enhance WI performance.

Fig.2: Wax and asphaltene interactions with comb like polymers (Adapted from:

Li et al. Energies. 2021; 14(24):8243. https://doi.org/10.3390/en14248243 )

Fig.2: Wax and asphaltene interactions with comb like polymers (Adapted from:

Li et al. Energies. 2021; 14(24):8243. https://doi.org/10.3390/en14248243 )

Fluids compatibility is a complex issue. Mixing incompatible crudes is known to destabilize asphaltenes, which affects wax deposition rates and chemical performance, as indicated above. Incompatibility with other injected chemicals is another issue that must be considered when selecting the chemical. A more complicated situation will arise if different crudes that are treated with different chemicals are mixed; in this case, crudes compatibility and chemicals compatibility must be studied and resolved.

- Water cut: chemicals are usually tested on net crude oil, while the water phase is not usually considered. The presence of water might affect wax deposition rates, asphaltenes behavior, and consequently the chemical performance.

■ Operational conditions:

Thermal history (heating or cooling) of the system. This affects the actual values of WAT, PP, and crude rheology. When applying the chemical, make sure you know the full thermal history of the crude oil being treated.

Some PPD performance is affected by flow rates, shear, increasing cooling rate, and high retention time in the system.

During injection, make sure the following points are checked :

- Proper solvent: fully solubilize the chemical, compatible with produced fluids, does not destabilize asphaltenes.

- Proper location: upstream WAT (10 -15 OC above WAT). That requires knowing the system design and its temperature profile.

- Proper dose must be maintained.

Hydrodynamics of the system. The treating chemical might solve wax issues in upstream locations where the chemical is well mixed with the stream and the high turbulence conveys wax particles. However, in downstream locations (especially in long pipelines) where the flow eventually slows down and the treating chemical capacity diminishes, it is anticipated that the fluid will start to drop the wax particles in these locations. In cases like this, section-wise treatment might be recommended, where WI is injected upstream WAT to prevent wax precipitation and WD is injected in the downstream section of the pipe when the flow slows down and WI efficiency deteriorates.

Extent of multiphase flow.

Further Reading:

- Hussein (2023), Essentials of Flow Assurance Solids in Oil and Gas Operations, Elsevier.

Wax Mitigation (1): Factors affecting wax control chemicals performance